Torque Wrench Calibration Services

What is a torque wrench and what does it do?

Torque wrenches play a critical role in ensuring safety and reliability across MedTech, aerospace, and biotech industries, where improperly fastened components can lead to equipment failure, contamination, or even catastrophic risk. In medical device manufacturing, they’re used to assemble precision components like implantable devices and surgical tools. In aerospace, torque wrenches help meet strict mechanical tolerances for airframes and propulsion systems. And in biotech labs, they ensure secure, sterile sealing of sensitive equipment such as bioreactors and filtration systems.

Why Choose SIMCO for Torque Wrench Calibration

When precision and compliance are non-negotiable, SIMCO delivers trusted torque wrench calibration services backed by over 60 years of experience. Our ISO/IEC 17025-accredited labs ensure every torque tool is calibrated to the highest international standards, whether you

operate in MedTech, aerospace, or advanced manufacturing. SIMCO offers a full suite of capabilities, including torque analyzer calibration, click- and dial-type torque wrench service, and traceable documentation for audit readiness. With a nationwide network and mobile torque calibration near me options, we make it easy to stay compliant and avoid downtime, right where you need it.

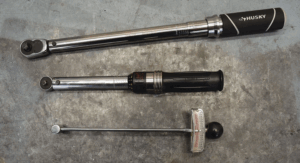

Types of Torque Tools We Calibrate

At SIMCO, we provide expert calibration for a wide range of torque tools used across regulated industries. Whether you're working on critical components in aerospace or precision assemblies in medical device manufacturing, our team ensures every tool meets exacting standards.

- Click-Style Torque Wrenches

We calibrate mechanical click wrenches to ensure consistent torque application and minimize risk of over- or under-tightening in production environments.

- Digital/Electronic Torque Wrenches

Our technicians handle complex digital wrenches with advanced settings, verifying electronic outputs and ensuring traceability to national standards.

- Beam-Style Torque Wrenches

For simple and rugged beam wrenches, we perform precise calibrations that maintain accuracy without relying on internal mechanisms.

- Dial-Type Torque Wrenches

Known for their readability and reliability, dial wrenches require fine-tuned calibration, especially for applications demanding tight tolerances.

- Torque Transducers/Sensors

We offer torque transducer calibration for inline and rotary sensors, providing the accuracy needed for R&D labs, automated systems, and quality control environments.

Our Torque Wrench Calibration Process

At SIMCO, our ISO 17025-accredited process ensures each torque tool meets the highest standards for accuracy and reliability. Here's how our step-by-step torque wrench calibration procedure works:

- Initial Assessment

We visually inspect the torque wrench for wear, damage, or signs of misuse to ensure it’s suitable for calibration.

- Pre-Calibration Testing

As-received readings are captured using certified torque wrench calibration equipment to assess any deviation from expected performance.

- Professional Calibration

Our technicians calibrate the wrench across its specified torque range, adjusting as necessary to meet manufacturer or client specifications.

- Multi-Point Verification

Torque is applied and measured at multiple points (e.g., 20%, 60%, 100% of full scale) to verify consistent performance throughout the operating range.

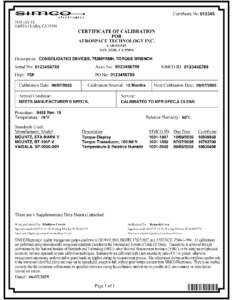

- Documentation

A detailed calibration certificate is generated, including measurement results, uncertainties, and traceability to NIST standards.

- Quality Assurance Review

Each job undergoes a final QA check to confirm that all procedures, tolerances, and documentation meet ISO 17025 requirements.

This meticulous process ensures your torque tools are not only accurate, but also audit-ready and safe for critical applications.

Torque Calibration Technical Specifications

SIMCO’s torque calibration capabilities are built for precision, reliability, and compliance with the highest industry standards. We service a wide range of torque tools—from fine medical instruments to heavy-duty industrial wrenches—under tightly controlled conditions that ensure consistent, repeatable results. Here’s what sets our process apart:

- Torque Range:

Calibrations from 1 in-oz to 20,000 ft-lb, covering both low-force applications and high-torque industrial tools.

- Accuracy Specifications:

Typical accuracy of ±1% of indicated value, meeting or exceeding industry requirements.

- Standards Compliance:

Calibrations performed in accordance with ASME B107.14, ISO 6789, and ANSI/NCSL Z540-1 standards.

- Calibration Equipment:

Utilizes high-precision torque transducers, reference torque analyzers, and NIST-traceable standards.

- Environmental Conditions:

Controlled lab conditions maintained at 23°C ±1°C with 30–60% relative humidity to ensure measurement integrity.

- Documentation:

Detailed ISO/IEC 17025-compliant certificates including as-found/as-left data, uncertainty calculations, and traceability.

When Should You Calibrate Your Torque Wrench?

Knowing when to calibrate is essential to maintaining both accuracy and compliance. Most manufacturers recommend a torque wrench calibration service every 5,000 to 7,000 cycles or at least once every 12 months, whichever comes first. However, there are several conditions that may require more frequent calibration:

- The wrench has been dropped or physically impacted

- It’s been overloaded beyond its rated capacity

- The tool is used in high-vibration environments

- It has been exposed to extreme temperatures or humidity

- There are signs of inconsistent or inaccurate torque readings

Industry-Specific Applications for Torque Calibration

At SIMCO, we understand that different industries demand different levels of precision—and our torque calibration services are tailored to meet those exacting standards.

- Medical Device Manufacturing

In MedTech, improperly torqued components can compromise the integrity of surgical instruments and diagnostic equipment. Our torque calibration services help ensure critical tools meet FDA and ISO requirements for safety, sterility, and mechanical reliability.

- Aerospace & Defense

From aircraft assembly to mission-critical military systems, torque accuracy is vital. SIMCO provides torque calibration services that meet the stringent specifications of the FAA, DoD, and major aerospace OEMs, helping teams avoid catastrophic mechanical failure and maintain airworthiness.

- Biotechnology

Precision torque is essential when assembling sensitive lab equipment or installing fittings in bioprocessing systems. SIMCO’s ISO 17025-accredited torque calibration services ensure proper sealing, leak prevention, and contamination control in regulated biotech environments.

Torque Wrench Maintenance Tips

To keep your torque calibration tool accurate and in top condition between calibrations, follow these practical maintenance tips:

- Reset to the Lowest Setting After Use

Relieves internal spring tension and helps prevent calibration drift over time.

- Store Properly

Keep the tool in a clean, dry, temperature-controlled space—preferably in a protective case.

- Avoid Physical Damage

Never drop your torque wrench or use it as a breaker bar. Impact can throw off calibration or damage internal components.

- Inspect Regularly

Check for signs of wear such as inconsistent clicking, loose parts, or faded torque markings.

- Clean With Care

Wipe down the wrench with a clean cloth after use. Avoid using harsh solvents that could damage the finish or internal mechanisms.

Proper care of your torque calibration tool not only extends its lifespan but also ensures consistent accuracy between scheduled calibrations.

Ready to get started?

✅ Request a Quote — Get pricing tailored to your specific multimeter and service needs.

✅ Find a Location Near You — Access SIMCO’s nationwide network of accredited labs or schedule on-site service.

✅ Explore Our Full Range of Calibration Services — From multimeters to oscilloscopes and environmental chambers, we cover it all.

When accuracy matters, trust SIMCO to keep your equipment compliant, audit-ready, and performing at its best.